Most of the warehouse racking layouts we create or work on at LIDD can be described as standard, meaning:

- Reach trucks are used to store standard 40” x 48” pallets in 2-pallet-wide racks on the 40” face

- Rack depth and load beam length dimensions are similar (42” or 44” deep uprights, with ± 96” beams)

- Aisle widths usually fall within a standard range (from 9’-6” to 11’-6”)

You might think that, from one project to the next, we reuse the same plans and elevations that we trusted to work in the first case. But the truth is that we haven’t drawn up the exact same layout twice. There are always differences in building dimensions, column spacing and other DC features that create a need for custom solutions.

Items that vary widely in shape, size or material present a specific challenge for the design of a warehouse’s pallet racking layout. Dealing with that challenge requires added thought, creativity and customization.

In recent years, LIDD has realized many projects of this kind for utility companies, city maintenance and transport, building material suppliers, furniture and appliance warehouses, etc. With these projects as with any other, we consistently strive to maximize storage capacity and maintain efficient handling. To achieve that goal when dealing with irregularly shaped items, we often have to use a variety of rack types and sizes that force us to adjust the layout. In cases where we have determined that certain items are best handled with special mobile equipment, for example, we have had to plan for special clearances and wider aisles. And then, in other cases, it turned out that favouring very narrow aisles, highrise shelving, or mezzanine sections led to the most optimal solutions.

In order to determine what solution best fits your needs, the first step is to collect good information on the products to be stored. Often clients that deal with products that differ greatly in size and shape don’t have complete dimensional data. In those cases, it may be necessary to measure the products. The rack specs can then be customized to fit the differing products. Customization efforts must however be tampered by the need to preserve the flexibility of the layout, which the proliferation of different storage unit types will negatively impact.

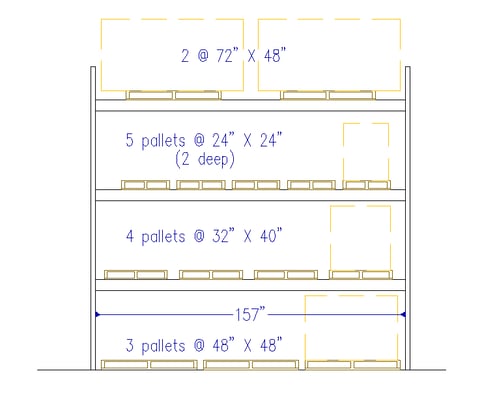

One way to maintain slotting flexibility is to find a “common denominator” load beam length that fits a variety of different pallet dimensions. The rack profile shown here holds pallets of various dimensions: 3 pallets that are 48” wide x 48” deep, 5 that are 24” x 24”, etc. In all likeliness, heavy duty wire mesh decks or extra pallet supports would be used to safely accommodate the differing pallet sizes.

You may also want to consider these additional rack types and accessories to store your oddly shaped items:

- Cantilever arm racks for pipes and long items

- Cantilever racks with continuous decks for furniture

- A-frame racks with vertical M-divider bars for long, on-end items

- Pallet cages to hold unstackable items

- Galvanized rack for exterior use

- Drum cradles and cable reel racks

- Shelving units for small parts

Whether your supply chain deals with irregularly shaped items or not, your distribution center will unavoidably have specific capacity needs that your racking layout design must take into account. Given the challenges posed by these capacity needs, it often proves financially advantageous to hire knowledgeable and experienced warehouse engineers to plan the new layout and oversee its implementation. So, before you invest your precious capital in a layout solution, contact us at LIDD for expert advice.