In his first post on column spans, LIDD’s warehouse layout expert Steve Zerter explained why 40’ column spacing is ideal for a pure single-deep layout. Here Steve explains how he tackles racking layouts in warehouses that have aisles wider than 40’.

One might think that wider building column centers are always better. In some cases, it’s probably true. Take manufacturing facilities, for example: in that environment, we generally find fewer equipment travel aisles and columns are therefore less likely to obstruct labour.

One might also think that 50 feet is a nice, round number. In my time as a warehouse designer, I’ve come across a few buildings with 50-foot column centers. Obviously, wider column spacing makes for larger spaces, which hints at the promise of more storage capacity. The truth, however, is that it is difficult to make good on that promise when designing racking layouts in a warehouse with wide column spacing. If one is not careful, 50’ column spacings may, in fact, turn out to have a negative impact on storage capacity.

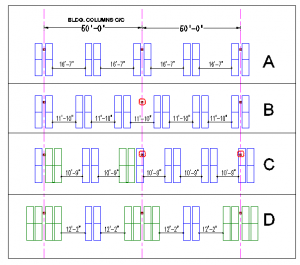

That is why fitting a racking layout that accommodates the standard 40’’ x 48’’ pallet in a facility with wide column spacing requires a bit more thought and ingenuity. Figure 1, below, gives an idea of the trial and error process I use when working with 50-foot column centers.

A: Pure single-deep with columns in the flue spaces.

That solution will not work. At 16’ wide, the aisles are far larger than they need to be, and the loss in net storage capacity is far too great.

B: Pure single-deep with standard aisle width.

Also not a good solution. While the aisles now have proper width, columns are found in the middle of them. Though we have solved the net storage capacity issues in A, the encumbered aisles will drastically reduce throughput capacity by slowing labor down: equipment will have to take alternative routes to access product and slots adjacent to columns in the aisles will be out of their reach.

C: Mostly single-deep, double-deeps added as needed to get the building columns out of the aisles.

A few pallet positions are sacrificed, but this is the best of the four options. It strikes the right kind of balance between maximizing storage capacity and optimizing throughput capacity – the aisles are sufficiently large and unencumbered for labour to achieve their tasks within the allotted time.

D: 2:1 ratio of double-deeps to single-deeps.

This pattern might work in some very specific DC environments, but it’s unlikely to be a good solution for most. While it successfully lands columns in the flues, the aisles are unnecessarily wide and the marginal gain in storage capacity (relative to C) is only apparent. Single and double-deep racks generally serve different purposes in a distribution center. To have them set up face to face in every aisle will more than likely cause operational problems that will slow down productivity and cancel the benefit of additional storage.

Laying out a building with unfriendly or inconsistent column centers increases the difficulty of finding the right balance between storage and throughput capacity. It is a game that entails playing with aisle widths and adding runs of two- or maybe three-deep storage to optimize the space. Inevitably, that will mean that some building columns end up within the racks, wasting pallet positions. Yet, often that sacrifice proves to be the better option to account for a DC’s slotting flexibility needs and help it meet its productivity targets.

Ultimately, one thing remains certain: while any column spacing can be accommodated, some spans – 40’ column spacings are ideal – are clearly more space efficient than others for pallet racking.