A member of this blog’s audience passed along a Software Advice article by Michael Koploy and asked for our comment. So here it is: yes.

Michael’s article describes five things a warehouse workforce needs to be efficient:

- Make the company’s leadership walk the floor and know the operations and its workforce

- Make individuals accountable for their performance – monitor, manage and correct it

- Put the workforce’s goals into the larger business context, letting workers know how they matter to the big picture

- Design processes that promote error-free working – ruthlessly eliminate systemic-sources of error

- Avoid over-engineering the processes and systems

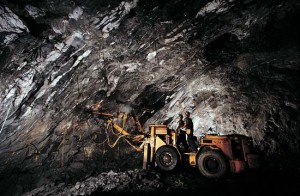

You can’t blame an engineer like me for wincing, slightly, at the last one. When I think back to my days in mining school, there was maxim about engineering that went something like this:

"The perfectly engineered mine is the one that collapses the minute you no longer need it."

Collapse too soon – under-engineer – and you have a potential human tragedy and most certainly considerable economic loss. That probably seems obvious.

However, not so obvious is when a mine collapses too late – decades after the last human set foot in it. That is the sign of an over-engineered mine where too much money was spent on support structures and development. Ultimately, this means capital investment irretrievably lost on digging a hole in the ground.

Distribution centers don’t have the same stark consequences from over-engineering or under-engineering. Still, over-engineering a distribution center has the same financial impact as over-engineering a mine as the operating expense results often don’t compensate for the heavy upfront investment. Ultimately, an over-engineered distribution center means capital investment is irretrievably lost on moving boxes around.

The last five years have taught us all how precious capital is and how lasting the damage caused by squandering it. Companies have rightly increased their focus on how capital is being spent. Supply chain executives need to ask themselves, before committing a staggering amount of capital on automating some part of their operations: will this capital deliver a quantum leap in cost competitiveness and service? If not, that capital is better spent somewhere else, like new stores or product lines.